|

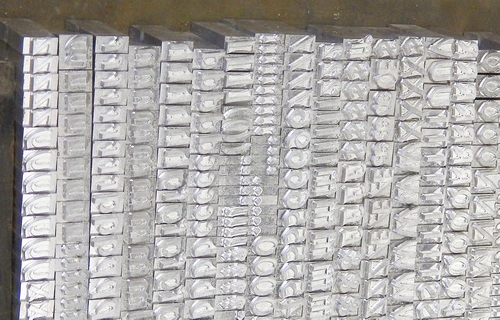

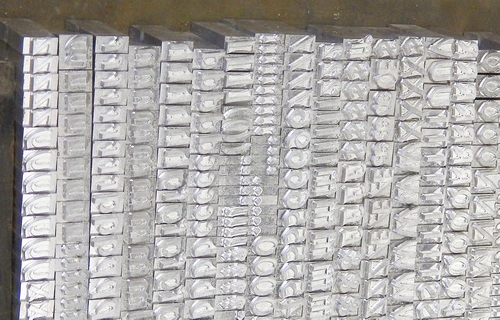

A stack of newly cast movable types produced in the foundry at MMOP. Type is produced

on the Monotype System using composition casters and Supercasters.

The foundry produces many well-known typefaces (book, display and fancy) in sizes

ranging from 6 point to 72 point, as well as spacing, rules and borders.

MMOP supplies type founts (as well as sorts and complete type-settings) to universities

and other museums. Other users of type including bookbinders, potters and enthusiasts

are also supplied.

|

|

Practicing the ancient craft of typesetting, Cynthia and Karen, interns from a Hong

Kong university, composing the text of a book. They are reading the words from their

"copy" and placing the types and spaces, one-by-one, into the composing stick.

When a line is complete, the space between words must be adjusted to totally fill

the line: each line must be exactly the same length. "Justified" means "fitting perfectly".

When a few lines are complete, the stick is "dumped" into the galley (printer's

tray) where the page gradually takes shape.

|

|

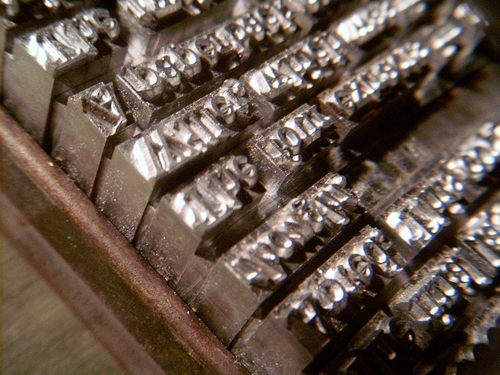

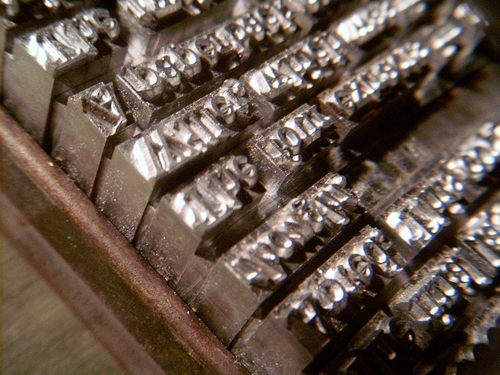

The classic image of some lines of type being composed in the composing stick.

Below the stick is a typecase carrying a fount [font] of movable type.

Note that the type is necessarily upside-down while being set, because the second

line must be set up after the first, and on top of it. Fortuitously this means the

flow is left-to-right, as the eye is used to reading. It is almost universal among

letterpress workers to read the type upside-down.

|

|

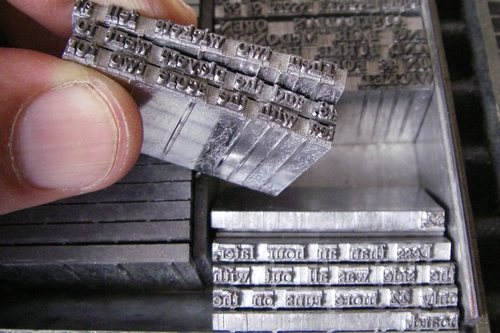

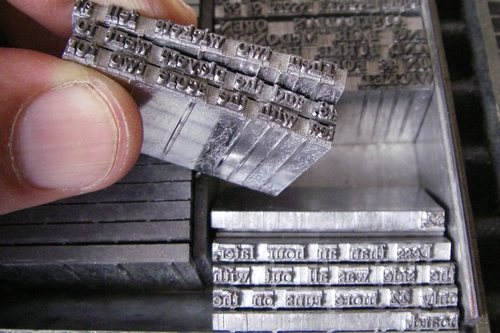

A close-up of the page of type from the book that Karen and Cynthia were composing.

You may notice that between each line of type there is a piece of metal spacing. These

spacing strips are called "leads" [pron: led]. Many items of type and spacing are made of

an alloy of lead, but only these strips are called by that name. Leads are made in a few

widths such as 3-point, 6-point, etc., and cut to length to suit the job.

The use of leads between the lines on a page is often called "leading" [ledding], and

the designer of the work decides whether to "set solid" or used leading to make the job

look lighter (some say "to give it air").

It seems in this case they required a thicker lead between paragraphs. Can you see it?

Can you spot the word set in italic type?

|

|

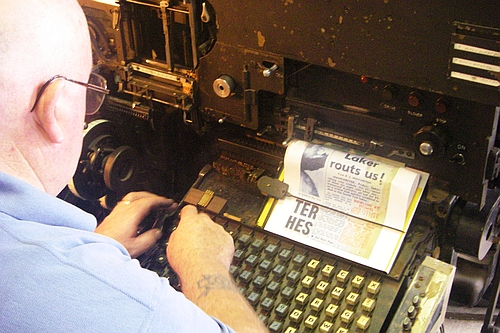

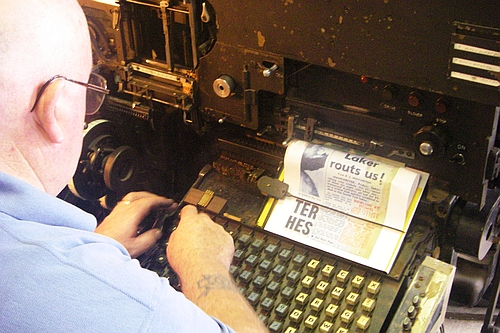

Laurie operating the Linotype (Model 78), setting the text for the Argus newspaper

reenactment.

Tapping a key releases a letter-matrix from the magazine into the "assembler". When a

complete line of "mats" has been assembled, the operator "sends it away" and the machine

does the rest automatically. The assembled line is transported to the casting part where,

closely against the mould, it is injected with molten metal.

The newly formed "slug" is solid almost instantly: it is then trimmed and ejected

into the galley where the entire story is built up, line by line. Meanwhile the mats are

returned to the magazine, each to its own storage channel. And also meanwhile, the

operator has probably composed the next one or more lines.

If the operator can type six lines per minute, the machine will keep up. A computer

operator cannot do any better.

|

|

The "slugs" of type produced by the Linotype. These slugs are part of "The Argus"

recreation set up at MMOP for the 50th anniversary of the closure of this, one of

Melbourne's leading newspapers, founded in 1846.

The Linotype : it is amazing to realise that this complex machinery was developed

about 125 years ago and it was improved, but not basically changed over its 90-year

life-span as the main method for composing newspapers around the world.

These slugs are "newspaper single column width". To the right of the column may be

seen a strip of type-metal that is as high as the type. This is a "typemetal rule",

and it prints the line (also called a rule) that is often required between columns.

|

|

MMOP certainly has automatic presses: you just load the type-forme and the paper,

start the motor and watch the printed sheets come out (ok, that's a bit simmpified).

But here a participant enjoys printing on a hand-fed, hand powered cylinder

press, learning at her own pace . . . she can see and control the whole operation.

For most of the workshops and experiences at MMOP, this is the way to learn and

understand the process of press operation.

|

|

|

ALL IMAGES AND TEXT ARE COPYRIGHT © MMOP 2016.

Please read

mmop.org.au/copyright.htm

|