|

Movable type composed by hand began to be superseded by mechanical

typesetting from around 1890. Mergenthaler's linecaster and Rogers' Typograph

led the way, and Lanston's Composition Typecaster quickly followed.

Mergenthaler's machine produces each line as a solid piece, "a line of type"

and it came to be called the "Linotype". Rogers' machine, also a linecaster,

was successful in its own way but was withdrawn from the market when Mergenthaler

bought the company from Mr. Rogers.

Tolbert Lanston's machine does not cast solid lines: it casts individual

types and the name Monotype helped distinguish it from the linecasters.

There were by that time a range of machines that would automatically cast

individual types but not compose. They would make movable types in bulk for

later setting by hand. But Lanston's system (two separate machines) had

a keyboard and it would make types in the required order to compose a text.

The Monotype Keyboard (seen here in the Showroom) is a separate machine from the Monotype Composition

Caster. The keyboard machine, operated by compressed air, punches the code-holes

into the 31-channel paper tape in response to taps on the various keys.

WARNING ! COMPLEX PARAGRAPHS FOLLOW.

As it does so it keeps track of the total width of the letters and spaces

in the line so it can know the space remaining in the line when the last letter

has been tapped. It can then divide that remaining space by the number of word

spaces to find the extra width that must be added to each word-space in the line in

order to exactly fill that line to the "measure" that applies to that story,

and that information is coded onto the tape.

The tape is then, or later, mounted onto the air-tower of the Monotype

Composition Caster. The air-tower reads the holes in the tape and controls

the operation of the caster.

The caster is set up by its attendant for each job. The set-up includes the

correct matrix-case and sizing-wedge for the typeface and size, the correct mould

for the size, the exact width ("measure") of the job, and any special characters

required (e.g. asterisk, percent, degree, accented letters, fractions).

The caster is capable of making three types per second but this speed is

only possible for very small typefaces because of the heat-load.

For each character, the caster reads the next frame of the tape, positions

the matrix case so that the matrix required for that character is located

over the mould aperture, adjusts, according to the sizing-wedge, the set-width of

the aperture to the width required for that character, raises the pump and nozzle

to form a metal-tight mating with the underside of the mould, discharges the pump

to fill the mould with molten metal, waits about 50 milli-seconds for the metal

to freeze, pushes the cross-block away from the aperture and brings the type

carrier to that position.

It then fully closes the type-mould blade to eject the newly-formed type into

the carrier, brings the cross-block back and the carrier back to be level with the

type-channel, and pushes the type into the channel where it takes its place in

the growing line of text. At that moment, the machine is casting the following

type.

All that can be done in one-third of a second.

The mould is cooled by a flow of water, without which the hot metal being pumped

into it would overheat the mould and it would be damaged. The heat load with larger type

(such as 12 point) is much greater than for 6 point, and the machine must run slower

with those larger sizes.

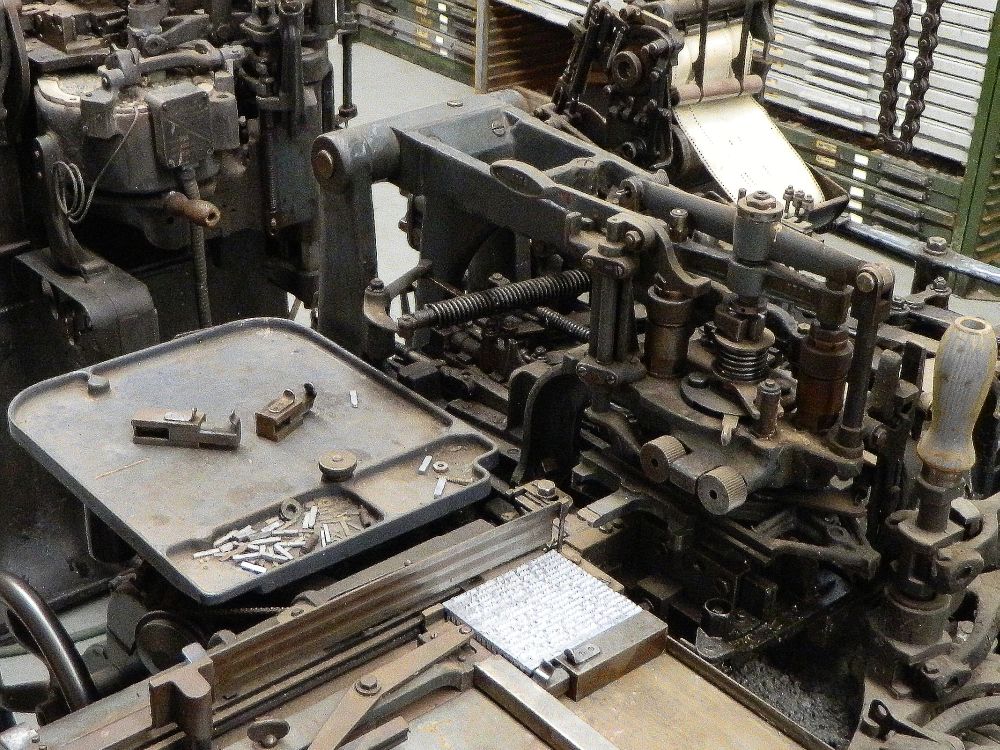

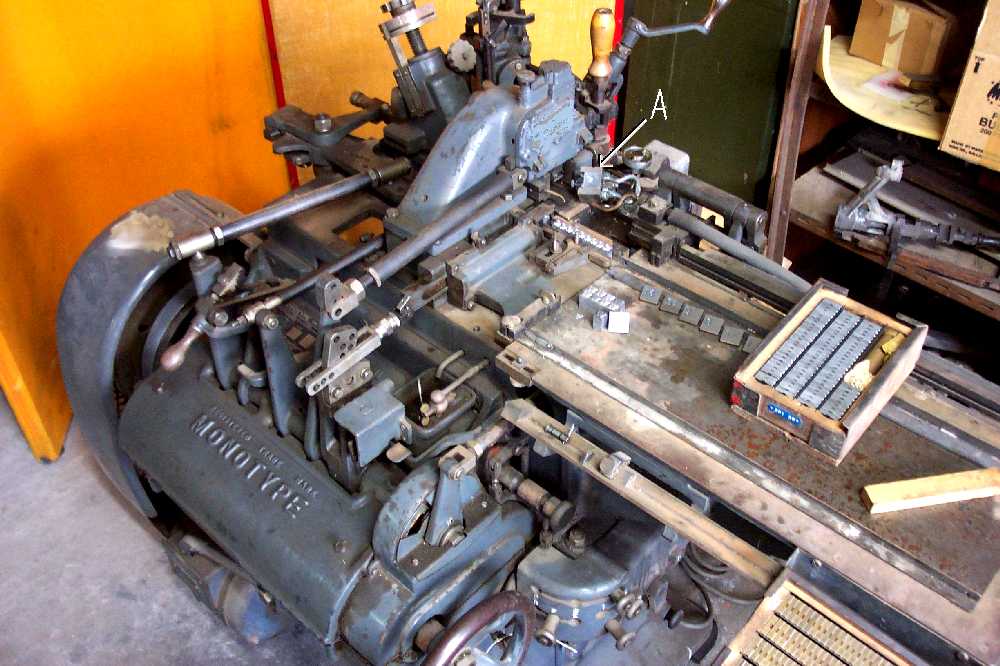

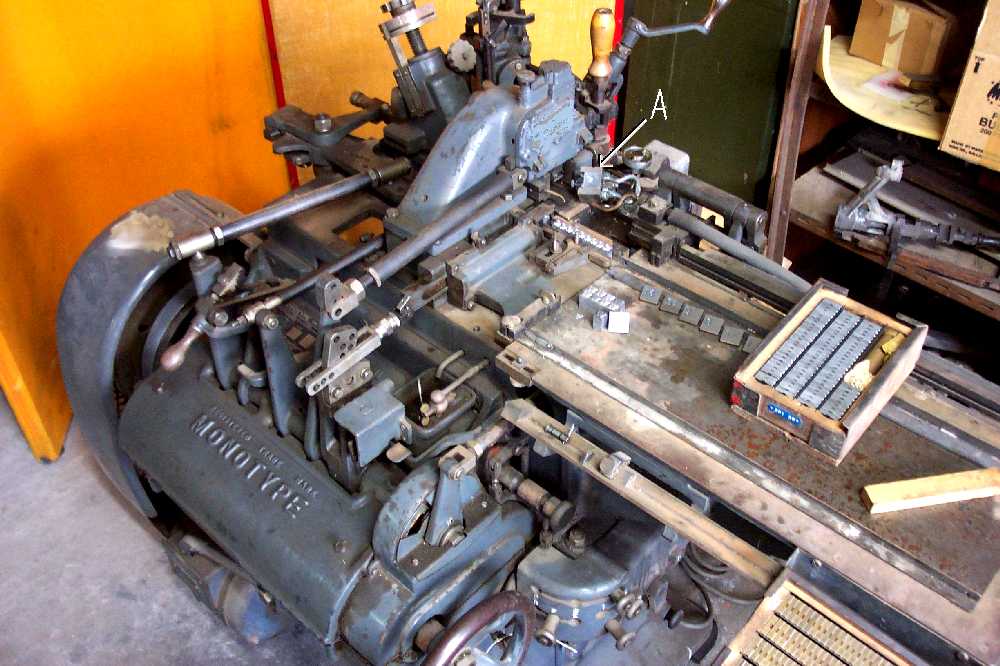

THE MONOTYPE SUPERCASTER AT WORK. A BOX OF MATRICES IS ON

THE TABLE OF THE MACHINE, AND A FEW HAVE BEEN PLACED ON THE TABLE. THE MATRIX HOLDER,

WITH A MATRIX IN IT, IS HIGHLIGHTED BY THE ARROW. A FEW NEW TYPES, JUST MADE, ARE

VISIBLE IN THE TYPE CHANNEL.

THE MONOTYPE SUPERCASTER AT WORK. A BOX OF MATRICES IS ON

THE TABLE OF THE MACHINE, AND A FEW HAVE BEEN PLACED ON THE TABLE. THE MATRIX HOLDER,

WITH A MATRIX IN IT, IS HIGHLIGHTED BY THE ARROW. A FEW NEW TYPES, JUST MADE, ARE

VISIBLE IN THE TYPE CHANNEL.

ON THE SHELF, BEHIND, IS A SPARE METAL PUMP: IN USE, THE BODY OF THE PUMP IS

SUBMERGED IN THE CRUCIBLE OF MOLTEN TYPEMETAL.

The Monotype Supercaster is not fully automatic. It is described as semi-automatic

as it needs its attendant to place the selected matrix into its holder and thence

into the space above the mould. The set-width required for each character also needs

to be set by the attendant, who would then start the machine and, usually, make a

quantity of each character before changing to the next one. These types would either

be made up into founts or laid into a typecase for hand composition.

The Supercaster most commonly produces type in sizes from 14 pt to 72 pt. If a user

did not have a composition caster, they could choose to use a Supercaster to make

smaller type (for hand setting) right down to 6 pt or less. The Supercaster has an

adaptation to produce other material such as strips of spacing and strips of

ornamental borders in any length.

.

.

.

|