THIS PAGE IS PART OF THE SUPPORTING MATERIAL FOR THE MEDIA REPORT ITEM BROADCAST ON 14 FEB 2008 ON THE MUSEUM.

|

|

|

MUSEUM HOME PAGE |

RETURN TO ABC PAGE ON THIS SITE |

LINOTYPE PIX |

OUR COLLECTION PIX |

ACTIVITIES PIX

|

RADIO NATIONAL NETWORK (AUSTRALIAN BROADCASTING CORPORATION)

THIS PAGE IS PART OF THE SUPPORTING MATERIAL FOR THE MEDIA REPORT ITEM BROADCAST ON 14 FEB 2008 ON THE MUSEUM. |

|

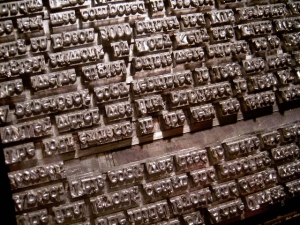

HAND TYPESETTING WITH MOVABLE TYPEPrinting of text took over from hand-written text in the period 1450 to 1550. It started when one Johannes Gutenberg invented a way to make unlimited quantities of uniformly sized letters (usually called type).Gutenberg was a jeweller by trade and he used his skill to cut, file or grind a piece of steel to make a punch of each required character. The punches are 'male' and wrong-reading (so they could print a right-reading character). The punch would print its character only for testing: when perfectly formed, it would be punched into a slip of softer metal (probably copper in those days) to produce a matrix. The matrix is 'female' and right-reading. In conjunction with a typecasting mould [mold in US] each matrix could then be used to produce those unlimited quantities of uniformly-sized types. Each type is an exact replica of the punch, although on a rectangular body. THE FOUNT A complete fount of type [pronounced like font, and spelt font in US English] may contain 90 or more different letters, figures, punctuation [points in printer's terms], ligatures and signs, and a total of hundreds or thousands of individual types, all of one size of one typeface. A fount is usually stored in a typecase (or a pair of typecases), from where the compositor (typesetting person) selects them one-by-one to assemble each line of text, reading from the copy (the wording supplied by the author). The lines are assembled in the hand-tool called a composing stick (or setting stick). The types are placed upside-down in the stick, and setting proceeds from left to right. Each word is separated from the previous one by a space. When the compositor finds that the next word will not fit in, the line is finished. Then the line must be justified by using thicker or thinner spaces between the words until the line is exactly tight. The next line is then composed on top of the completed one. When the stick is almost full (with several completed lines) it is dumped. The lines are carefully removed and placed into a galley, a special tray with three raised edges. (Printing firms usually had thousands of them.) the Galley is placed on a sloping worktop. The the next stickful is added, and so on, until a page or 'take' is completed. The new page of composed type is then stabilised by tying it up with page cord (string, in other words). A single copy of the tied-up page is then printed. This is the galley proof, which is then compared to the original copy. Any errors will be corrected by the compositor and the page is proofed again. Eventually the pages are locked up into a printing forme and find their way into a printing press. There, ink is applied to the surface of the type and a sheet of paper is pressed onto it to receive the impression of the text. This process, whether printed by hand or automatic press, and whether type-set by hand or the Linotype or similar systems, is described by the name Letterpress or letterpress printing. ANY QUESTIONS? CONTACT US |

| |

| ||

| ||