THE LINOTYPE - MMOP video clip from 2005.

WHAT IS A LINOTYPE MACHINE?

Invented around 1890, these machines produce type for printing. Instead of standing on front of a type-case picking up individual letters of movable type, the compositor sits at a keyboard and taps keys. The machine produces each line in one solid piece (a Line o' Type) instead of single letters. These solid lines of type are generally called 'slugs'. Slugs of type are compatible with movable type and the old and new methods can be mixed in the one job, as needed. The Linotype and similar machines are classed as 'line casters'.

The output per man-hour is about five times greater than the traditional way, so these machines were very popular with printing firms and publishers. Not so popular at first with the workers!

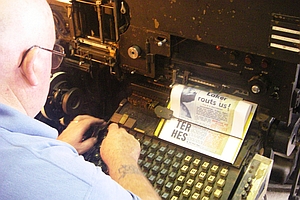

Former volunteer Laurie, a retired printing compositor, is seen first checking, then closing up, the Linotype mechanism. This 1960s machine is not fundamentally different from the first Linotypes made around 1890. A city newspaper office could have 50 or 100 of these in one large noisy room.

|

After a quick view of the leather belts that power various parts of the machine, we see Laurie at the machine, reading the written words and typing them on the keyboard. Each key that he taps releases a letter-mould (called a mat) (matrix) from the related channel in the storage magazine. There are 90 keys (and 90 channels). Each mat drops down to the assembler where a line of words is created. |

When the line is complete, the impressive camshaft turns, operating various levers that move the line of mats and the metal crucible and its pump. The line of mats moves in front of the line-mould. When the metal-pump goes down, the mould and the mats are flooded with type-metal, molten at 300 degrees, and a "line of type" (slug) is cast.

The line of mats is then transported to the top of the machine where each mat is returned, almost magically, into the channel from whence it came.

By that time, Laurie will have composed two more lines.If the operator can compose six lines per minute, the Linotype can keep up.The new slug, on its way out of the mould, is trimmed to exact size and then joins the other lines.When the typesetting "job" is completed, the lines will be placed into a printing press, probably with other kinds of type, spacing, images and rules; then it is inked [pictured] and pressed into paper.

|

|

CLICK HERE TO WATCH THE LINOTYPE 1m 16s (file type is .mp4)

MAY NEED TO USE "GO BACK" FUNCTION WHEN VIDEO IS FINISHED

INTERESTING: The film and TV industry has noticed MMOP and used the Museum as a filming location several times and at other times picked up a truckload of machines and other things to use on their set elsewhere. Twice in recent times the MMOP "Newspaper Linotype Composing Room" has been used for TV. Here's one of the episodes taking place.

MMOP Home Page

back to the MMOP Rebuild Page

Updated 20220128